Loading... Please wait...

Loading... Please wait...- Home

- Sewer Catagory Products

- POWDER CRYSTAL GRANULAR ENZYMES BACTERIA DRY

Categories

POWDER CRYSTAL GRANULAR ENZYMES BACTERIA DRY

Product Description

POWDER ENZYME BACTERIA DRY

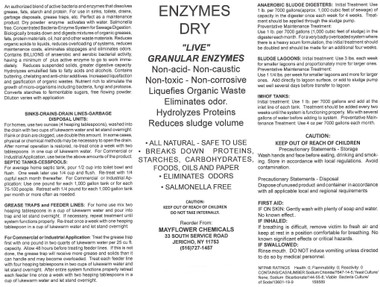

septic tank enzyme treatment can solve your sewer waste problem like the pros do in municipal sewer departments. Try our active, living, industrial-strength, powdered enzymes to unleash their robust waste-digesting attributes. This extraordinary, all-natural dry bacteria and supplemental enzymes product is specifically formulated for sewerage treatment processes. This vociferous blend of exceptional aerobic and anaerobic bacteria strains is cultured for efficacy, swift action, and no odors, thereby augmenting system capacity. We enhance our powder with all-natural enzymes to instantly digest animal and vegetable sources of FATS, OILS, GREASE, SLUDGE, ORGANIC WASTE, CARBOHYDRATES, STARCHES, PROTEINS, and PAPER (cellulose) products. This amplifies trouble-free activity in the system. Our product is powerful and safe to use!

Septic tank enzyme treatment is best to solve your problem of sluggish and small volumes of waste being treated. Meet or exceed even the strictest effluent condition standards! Avoid frustrating interruptions created by harmful influent. Our flourishing bacterial colonies are perfect for use in various sewage treatment mechanisms, as well as GREASE TRAPS, LIFT STATIONS, SINKS, TUBS, DRAINS, PLUMBING, FEEDER LINES, TRICKLING FILTERS, WET WELLS, LAGOONS, SEPTIC TANKS, CESSPOOLS, DRAIN FIELDS, LEACH FIELDS, AEROBIC/ANAEROBIC SLUDGE DIGESTERS, HOLDING TANKS, IMHOFF TANKS, BOAT HOLDING TANKS, and RV and MOTORHOME TANKS.

Diminish sludge quantity. Scale down disgusting odors. To avert undesirable bacteria that cause noxious gases and ghastly stench, our good bacterial enzymes need to be applied on a preventative maintenance schedule. Regular applications allow the systems to operate at peak efficiency. This also refreshes the supply of favorable bacteria, thereby minimizing COD and BOD efficiently and rapidly. Use confidently in anaerobic and aerobic sludge digesters for effortless dewatering, maximum biological oxidation, boosted nutrient amount, and smaller volume.

- EPA APPROVED, GREEN, and registered in your state

- ALL-NATURAL, BIOFRIENDLY enzyme-producing bacteria

- EXTRA BONUS of ALL-NATURAL enzymes

- IMMEDIATE enzyme action

- Multiplying bacteria renews enzyme action

- Regular application for operations and traps efficiency

- Bacteria population doubles every 20 minutes

- Bacteria feed on ORGANIC WASTE

- Bacteria create enzymes that digest FATS, GREASE, OIL, and PROTEIN waste

- MINIMIZES FOUL ODORS

- PROUDLY MADE in the USA

- MADE in AMERICA

DIRECTIONS:

IMPORTANT!!! The dry bacteria and enzymes in this formula MUST ALWAYS BE ACTIVATED by PRESOAKING them in warm water (85 degrees – 100 degrees F). DO NOT USE HOT WATER!!! Pour this slurry directly into the waste stream where adequate mixing will be achieved.

SEPTIC TANKS/CESSPOOLS:

Commercial or Industrial: Use ½ cup of presoaked enzymes for each 500-gallon capacity daily for the first week. Re-treat with ¼ lb. for each 500-gallon capacity thereafter. Home Use: Pour ½ cup of presoaked enzymes into toilet and flush. One week later use ¼ cup and flush. Re-treat with ¼ cup each month thereafter.

SEWAGE TREATMENT PLANTS:

Use in all treatment processes where waste digestion (biological oxidation) takes place. The usual first point of addition is immediately after the primary clarifier. Add this bacteria culture to the liquid waste as it flows from the primary clarifier into the secondary treatment system.

WET WELLS, LIFT STATIONS, SEWER MAINS, AND LATERALS:

Add 1 ½ pounds per 500 cubic feet directly into wet well. Digestant must get into liquid in order to activate. Treat laterals during periods of low flow by adding through manholes:

LATERAL DIAMETER (inches) POUNDS/500 ft.

8 inches – 1 pound 12 inches – 1 ½ pounds

16 inches – 2 pounds 20 inches – 3 pounds

24 inches – 4 ½ pounds

Sludge must be treated separately from the liquid waste after the primary clarifier.

Aerobic Digesters: Use 2 pounds per week per 1000 cubic feet of sludge. When a heavy scum blanket or grease layer is present, a double strength treatment is recommended.

Anaerobic Digesters: Use same application rate as aerobic digesters. The product works in harmony with anaerobic methane-producing bacteria to provide more complete digestion and steady gas production.

In smaller treatment plants, add to: Settling Tanks: Use 1 to 2 pounds per week for each 1000 cubic feet of capacity. Imhoff Tanks: Use 2 pounds per week for each 1000 cubic feet of tank capacity. Distribute over surface of the solids beneath gas vents, then agitate the entire mass by paddle or water hose.

Lagoons, Oxidation Ponds, Polishing Ponds: To reduce odors and sludge build-up and improve clarification, use 1 to 2 pounds weekly per 50,000 gallons of capacity. Disperse the digestant over the water, or add through a wet well, OR…

Lagoons Per Acre: Initial Treatment: Use 10-25 lbs. of presoaked enzymes per acre surface for the first day. Apply directly to lagoon or to sludge pump wet well several days before transfer to lagoon. Maintenance: Use 1-2 lbs. presoaked enzymes per acre surface once per week.

Trickling Filters: Use an initial treatment of 40 pounds (or 6 to 12 pounds/million gallons of daily (low) through wet well or siphon tank. If necessary, repeat treatment within 48 hours. For preventative maintenance, use 3 to 6 pounds weekly for each million gallons of daily flow.

Oxidation Tank: In properly aerated tanks, use 3 to 6 pounds for each million gallons of liquid sewage. Because of the high bacteria, residence times in oxidation tanks may be reduced accordingly.

PACKAGE PLANTS: Activated Sludge: Apply presoaked enzymes at the point of entry just prior to the aerated portion of the waste treatment plant according to the following table:

Plant Size First Week Maintenance

Up to 10,000 gpd ¼ lb./day ¼ lb./week

10,000-50,000 gpd ½ lb./day ½ lb./week

50,000 gpd or more 3 lbs./MGD 1 lb./MGD